A street could receive its name for many different reasons, the most common being as a tribute to someone famous. This year in August, however, Mohelnice chose to name a street after a technology. Its name—Aditivní—is of course a reference to the additive technology and also to our company, One3D, which has been based there since 2020.

Additive technologies

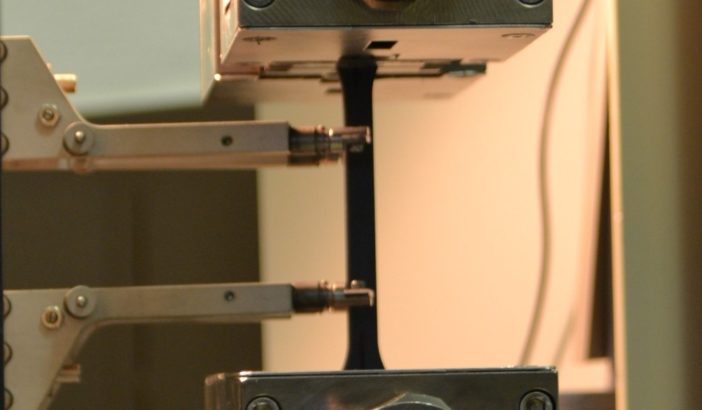

The term “additive technology” is not exactly something a layperson would recognize, but when we mention industrial 3D printing, most people know what we mean. The “industrial” part is very important, though, because it is fundamentally different than regular 3D printing. Instead of, for example, melting a filament to print a little whistle, additive manufacturing creates products from a powder subjected to a laser beam. This powder is not limited to plastic raw materials alone, they can also be ceramic or metal. In Aditivní Street, there is a company called One3D, a unique center of technology within Central Europe. In a sense, additive manufacturing is the exact opposite of common industrial manufacturing. Machining removes material from the processed part, but additive machines build products from scratch, layer by layer, adding material instead.

“The fundamental difference between additive technologies and all of the others is twofold. First, additive technology allows you to design and produce a part with basically any level of topological complexity. And second, the final piece is created only by adding, not subtracting, excessive material, which means that much less waste is produced,” says Tomáš Dokoupil, company CEO.

Powder, which the industry printer applies in layers, is usually fused with a high-power laser. Parts “printed” like this are, due to their homogeneity, resilient and highly functional. And they can transform entire industries and human lives. This technology is used to manufacture prototype parts, but in recent years it also started to produce final pieces.

“These could be, for example, components of dentures, either from metal or ceramics. They could be replacements of cranial bones and joints made from titanium alloys, and other components of the human body. A large number of components, like bladed wheels or jets for jets engine, are now being utilized by the aviation industry or energy industry. Prototype parts can be found in the automotive industry, but also in consumer electronics. We produce functional prototypes of entire headlamps,” explains David Paloušek, CTO of the company.

Modern method of production

The history of additive manufacturing dates back somewhere into the 1980s. The first technology, based on the principle of hardening a photopolymer using laser, is called stereolithography. Today, when people hear the term 3D printing, they mostly think of the models made of plastic filament, made famous in our country by Josef Průša with his brand of printers. The main additive technologies, used in the center in Mohelnice as well as around the world, include Selective Laser Sintering, Multi Jet Fusion and Direct Metal Laser Sintering.

Here is a small glossary:

- SLS (Selective Laser Sintering) works with powdered plastic materials, most often nylon PA12, fused together using a laser beam.

- MJF (Multi Jet Fusion) works with nylon, but instead of a laser, it uses the application of heat.

- Direct Metal Laser Sintering (DMLS) works with powdered metal materials, like aluminum alloy, which are fused together with a laser beam.

These modern production methods not only have less negative impact on the environment and reduced carbon footprint, they also generate much less waste. Material is simply added only where it is needed. Our environmentally friendly approach should be apparent from this and from the other planned activities of ONE3D.

“Our corporate culture builds on the foundation of accepting one’s own responsibility, which could also be explained by the saying: ‘Every man is the artisan of his own fortune.’ We try to be responsible not only towards ourselves and our clients, but also towards natural resources. A new part of our workshop will be a green roof, we also plan to have a natural biotope there, our own bee colony or outdoor offices,” says Filip Dokoupil, company CVO.

Do you need parts that you know how to imagine, but not how to produce? Maybe you just want to set the boundary conditions and let advanced computer algorithms create an effective design for your part? Now you know where to go. Additive Street offers all the technology and know-how you need, all in one place.