About HP PA12

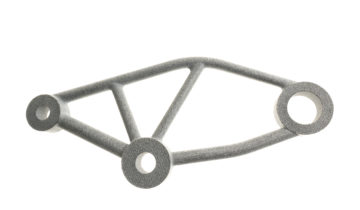

This multipurpose PA12-based material has good mechanical properties while being chemically resistant to oils, greases, aliphatic hydrocarbons and alkalis.

Suitable uses

HP PA12 is a suitable alternative for injection molded plastics. Its very affordable price makes it suitable for serial parts or prototypes and end-use parts where balanced mechanical properties are required. The material can also be used for the production of orthotic appliances.

Specific applications

- prototype parts

- guiding elements for various media

- orthotic devices

Technological specifications

| Standard delivery time | 4 working days |

| Production accuracy | ±0.2% (with lower limit ±0.2 mm) |

| Production layer | 0.08 mm |

| Minimum wall thickness | 0.5 mm (preserving properties 1 mm) |

Datasheet

| Tensile strength | 48 MPa |

| Modulus of elasticity | 1700 MPa |

| Relative elongation | 20% |

| Heat distortion temperature HDT 1.8 MPa | 106 °C |

| Heat distortion temperature HDT 0.45 MPa | 175 °C |

Download datasheet

Keep everything in one place. Download the datasheet of all our production materials.

Download datasheetMaterials

Metals

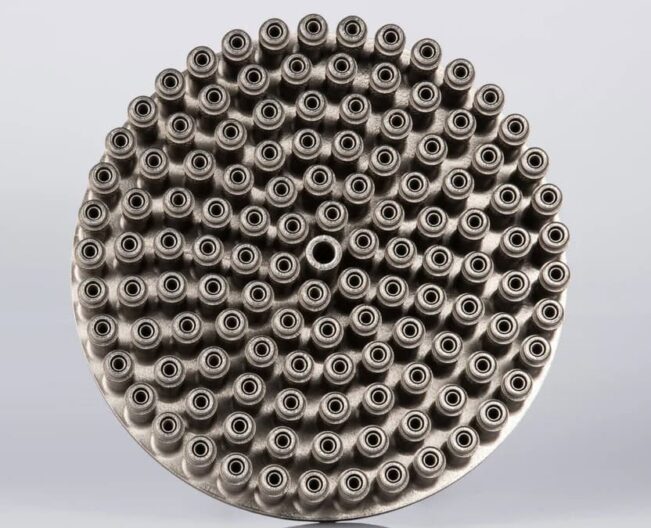

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS)

Inconel 718

Plastics

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS)

PA2200

Plastics

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS)

PA3200GF

Plastics

Stereolithography (SLA)

Stereolithography (SLA)

WaterClear

Plastics

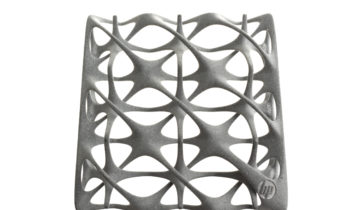

Multi Jet Fusion (MJF)

Multi Jet Fusion (MJF)

Ultrasint TPU

Metals

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS)

Tool steel 1.2709

Metals

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS)

Stainless steel 1.4404

Metals

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS)