Key features

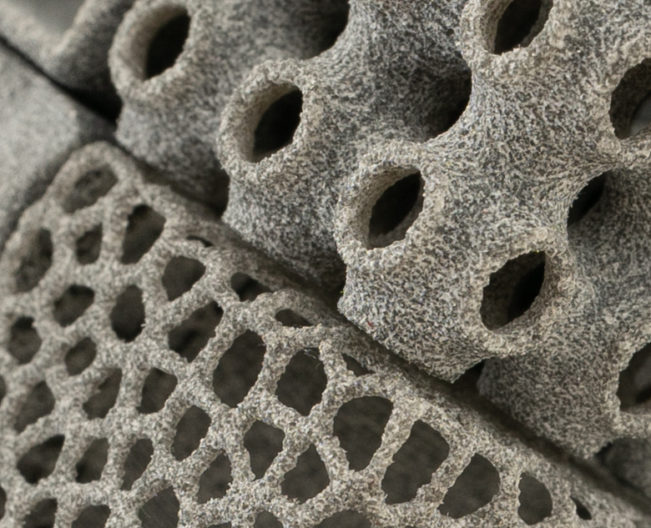

Inconel 718 is a precipitation hardened nickel-chromium alloy with good tensile strength and yield strength, good fatigue behaviour, good high temperature tensile strength up to 700 °C. Parts printed from Inconel 718 can be further processed by conventional technologies such as machining, electroless plating, etc.

Suitable uses

The material is ideal for many high temperature applications such as gas turbine components, instrument parts, components for the power and process industries, etc. It also has excellent potential for cryogenic applications. Due to the lay-up method, the parts have a certain anisotropy.

Specific applications

- turbines, exhaust systems, engine parts for aerospace industry

- steam generators, gas turbines and other components for the energetic sector

- components for high-performance engines in the automotive industry

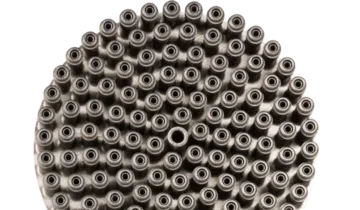

Technological specifications

| Standard delivery time | 10 days |

| Production layer | 0,04 – 0,08 mm |

| Minimum wall thickness | 0,5 mm |

| Maximum part´s dimensions | 390 x 390 x 390 mm |

Datasheet

| Status | Without heat treatment | Precipitation hardening | ||

| Orientation | XY | Z | XY | Z |

| Tensile strength Rm (MPa) | 1060 | 980 | 1500 | 1430 |

| Yield strength Rp0,2 (MPa) | 750 | 630 | 1250 | 1200 |

| Elongation at break ε (%) | 25 | 29 | 12 | 13 |

| Hardness Vickers HV | – | 467 | ||

| Density ρ (kg/m3) | 8250 | |||

Download datasheet

Keep everything in one place. Download the datasheet of all our production materials.

Download datasheet