Key features

Martensitic precipitation curable tool steel 1.2709 (MS1) is characterized by very high hardness, strength and yield strength, which can be further improved by heat treatment.

Suitable uses

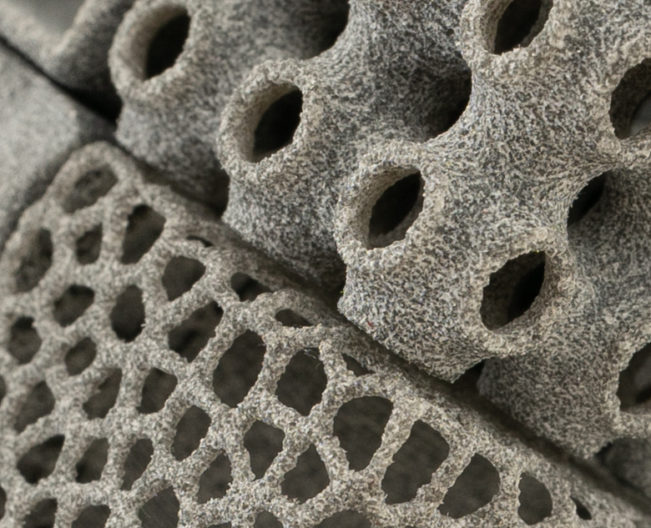

Due to its excellent mechanical properties, this material is used in a wide range

of engineering applications, such as injection moulds, where the additive manufacturing potential can be used to create internal conformal cooling cavities.

Specific applications

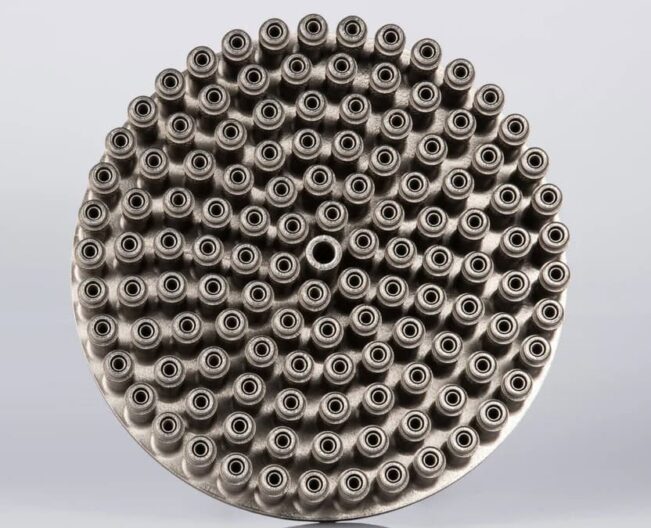

- shape insert including conformal cooling in injection tool

- components with high requirements for strength, hardness and abrasion resistance

- prototypes of sheet metal parts of the seat for the automotive industry

Technical specifications

| Standard delivery time | 10 days |

| Layer height | 0.04 mm |

| Minimum wall thickness | 1 mm |

| Maximum part dimensions | 390 x 390 x 390 mm |

Datasheet

| Condition | No Heat Treatment | Precipitation Curing | ||

| Orientation | XY | Z | XY | Z |

| Tensile strength Rm (MPa) | 1200 | 1200 | 2060 | 2080 |

| Contractual Yield Strength Rp0.2 (MPa) | 1020 | 1050 | 1990 | 2010 |

| Elongation at break ε (%) | 13 | 11 | 4 | 3 |

| Rockwell Hardness HRC | – | 50 to 57 | ||

| Density ρ (kg/m3) | 8000 to 8100 | |||

Download datasheet

Keep everything in one place. Download the datasheet of all our production materials.

Download datasheet