What is it?

Abrasive blasting is the treatment of a surface with small particles, which are intended to clean or remove the blasted surface and thus modify its structure.

For metal parts we use corundum abrasive particles, for plastic parts we use ballotini and ceramic balls.

What is it used for?

In the additive industry, we use abrasive blasting to clean extracted parts produced using powder technologies.

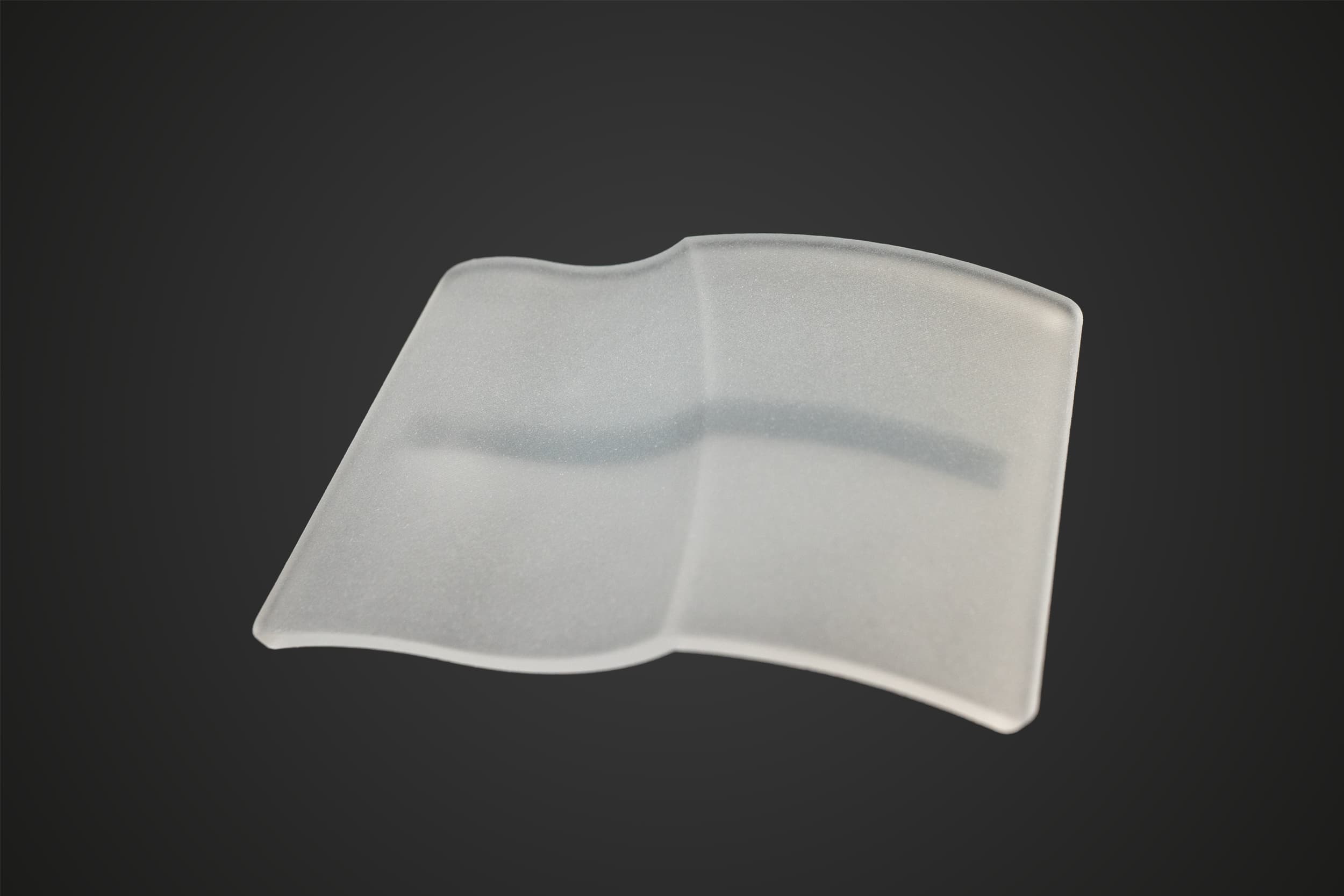

This process helps perfectly clean the adhered powder and unify the surface

of the part.

Main advantages

- roughness reduction

- surface cleaning

- surface unification

- surface treatment SLA parts

Technological specifications

| Maximum part size | 700 x 700 x 500 mm |

| Abrasives used | ballotini, ceramic, corundum |

| Compatible materials | PLASTICS – PA2200, PA3200GF, HP PA12, HP TPU, WaterClear

METALS – AlSi10Mg, 1.4404(316L), |