What is it?

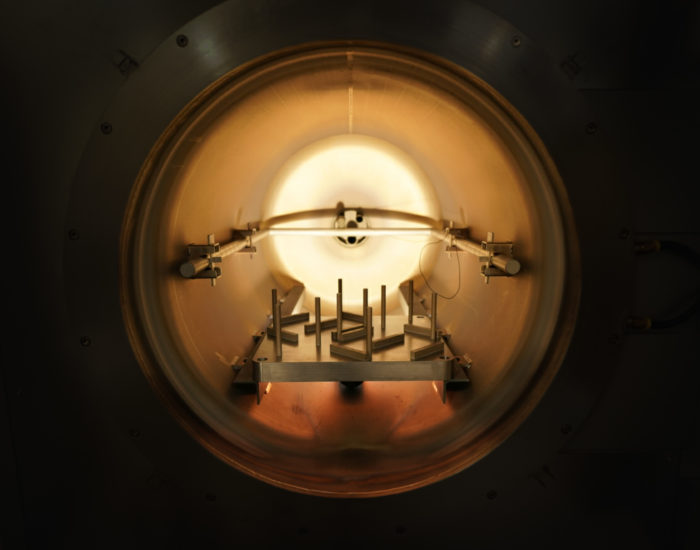

A material processing process that primarily affects the microstructure and material properties of alloys. The part is heated and cooled in a controlled manner

in a protected atmosphere in a furnace. Heat treatment takes place at defined temperatures and times.

What is it used for?

Heat treatment is the basic technological treatment of ferrous and non-ferrous metals in order to modify mechanical and material properties such as strength, ductility, elasticity, microstructure, etc.

Main advantages

- Improvement of mechanical properties

- Stabilization of AM parts

- Reduction of internal stress of AM parts

Technological specifications

| Maximum part size | 800 x 400 x 400 mm |

| Protective atmosphere | argon |

| Compatible materials | Aluminum alloy AlSi10Mg, Tool steel 1.2709 (MS1), Stainless steel 1.4404 (316L) |