What is it?

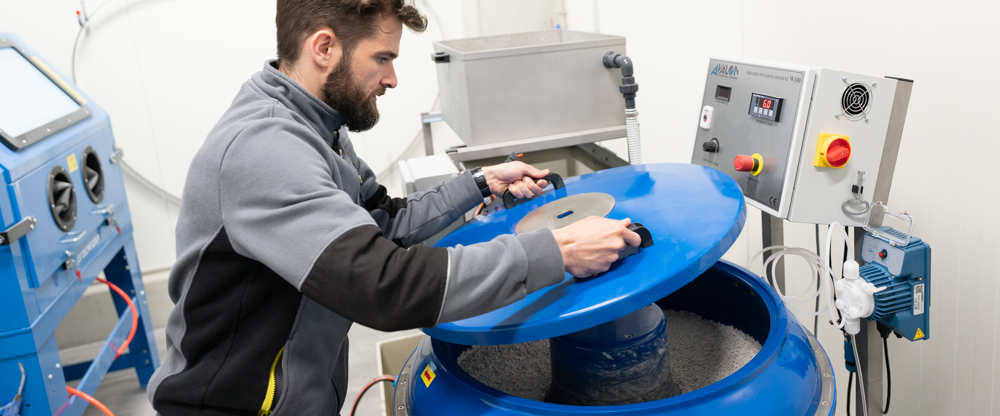

This mechanical or mechanical-chemical surface treatment process is based

on the use of tumbling bodies and water with a special admixture adjusting the pH.

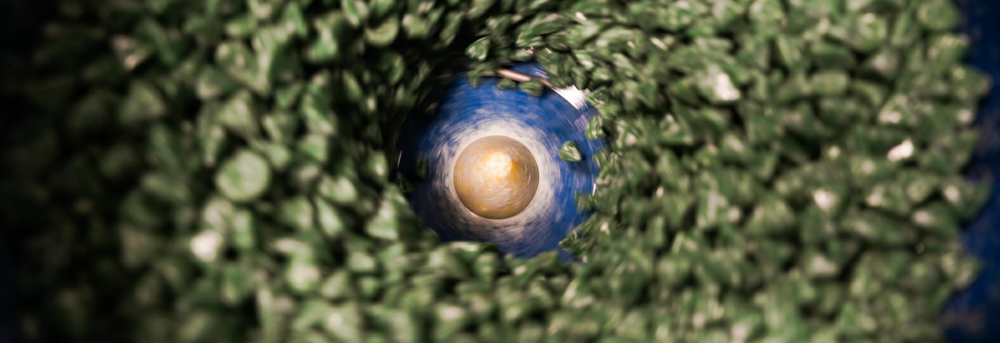

Due to vibration, relative movement occurs between the part and the bodies,

which gradually gently abrades its surface.

What is it used for?

Tumbling is often used as a surface pretreatment prior to electroplating or coating, especially for smaller components.

In the case of 3D metal printing, it is also used to achieve a final surface with a smooth and glossy surface.Vibration tumbling eliminates surface defects and improves performance.

Main advantages

- surface unification

- reducing surface roughness

- surface polishing

Technological specifications

| Maximum part size | Ø 200 x 200 mm |

| Abrasives used for tumbling | ceramic, plastic and porcelain media |

| Compatible Materials | AlSi10Mg Alloy, Stainless Steel 1.4404 (316L), Tool Steel 1.2709 (MS1) |